QUALITY ASSURANCE

QUALITY ASSURANCE

Quality Assurance Excellence at Minerva Machinery

At Minerva Machinery, we prioritize quality assurance throughout every stage of our manufacturing process. Our commitment to excellence is reflected in our rigorous certification standards, meticulous documentation practices, and unwavering dedication to customer satisfaction.

Quality Policy

At Minerva Machinery, our fundamental mission is unwavering: to prioritize “Customer Satisfaction” across all stages of our operations. We achieve this by:

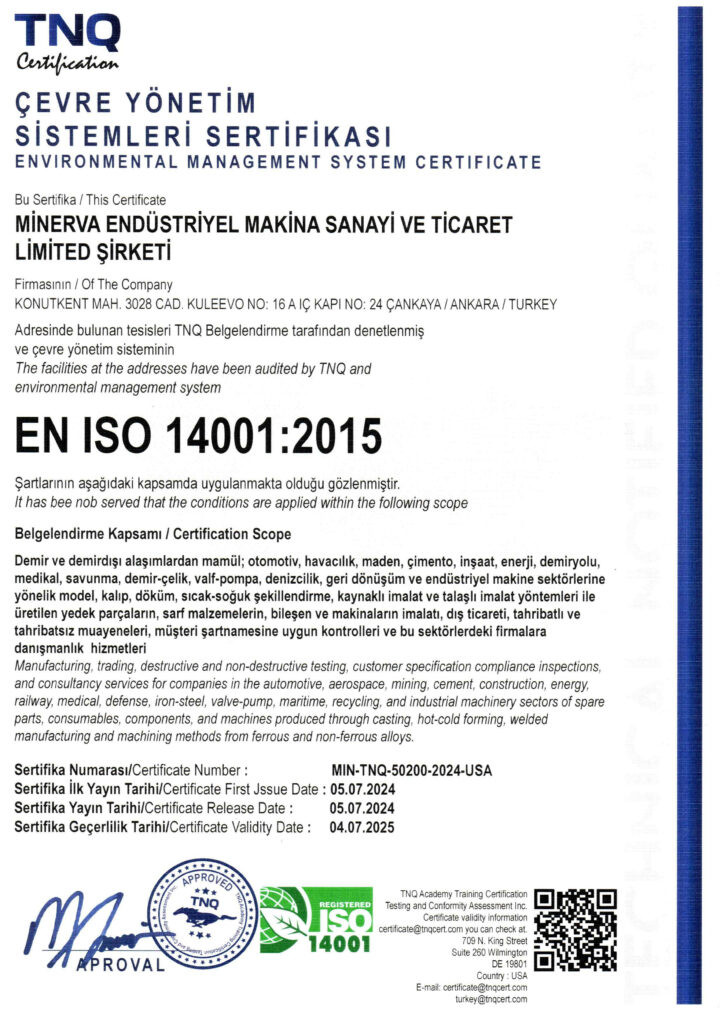

- Meeting and exceeding customer needs and expectations in accordance with ISO 9001, ISO 14001, and ISO 45001 standards.

- Establishing enduring partnerships with our customers as their trusted solution provider.

- Upholding the esteemed reputation of our company through consistent delivery of excellence.

- Embedding a culture of continuous improvement into every aspect of our operations and team mindset.

- Optimizing resource utilization while perpetually enhancing our services.

- Fostering a collaborative team spirit, promoting awareness of quality, environmental, and occupational health and safety among all employees.

- Cultivating our team dynamics akin to a harmonious family environment.

- Ensuring ongoing enhancement of our quality, environmental, and occupational health and safety performance.

- Proactively preventing environmental pollution and maintaining a safe working environment in compliance with occupational health and safety legislation.

- Taking decisive actions to control and improve the effectiveness of our continuous improvement, environmental, and occupational health and safety management policies, while considering risks and opportunities.

This is the cornerstone of our Quality, Environment, and Occupational Health and Safety Policy. As part of the Minerva Machinery family, we are dedicated to embracing and implementing these principles in all aspects of our operations and business practices.

Certification & Documentation

Our commitment to quality assurance is underpinned by meticulous certification and documentation processes:

- Material Certifications: We provide comprehensive documentation for all raw materials used in production, ensuring transparency and quality assurance.

- Thorough Process Documentation: Every step of our manufacturing process is meticulously documented, from casting to machining, finishing, and inspection.

- Robust Quality Control Plan: Our detailed quality control plan outlines strict inspection procedures, tolerances, and criteria for acceptance, guaranteeing the highest standards of quality.

- Comprehensive Inspection Records: We maintain thorough records of inspections conducted at every stage of production, ensuring accountability and traceability.

- Regular Equipment Calibration: Our commitment to accuracy includes regular calibration of equipment to uphold precision and compliance with industry standards.

- Traceability System: We implement a robust traceability system, allowing products to be traced back to specific raw material batches and production processes.

- Prompt Non-Conformity Resolution: Any non-conformities identified are promptly documented, and corrective actions are taken to maintain our commitment to excellence.

- Continuous Employee Training: Our team undergoes continuous training and qualification to ensure they are equipped with the skills and knowledge necessary to uphold our quality standards.

- Transparent Customer Documentation: We provide customers with transparent documentation, including material certifications and inspection reports, to instill confidence in the quality of our products.