FORMINGS

FORMINGS

Forming Services

Precision Moulds for Superior Forming Results

At Minerva Machinery, we specialize in crafting high-quality moulds for forming processes that ensure exceptional precision and durability. Forging moulds are crucial tools used to shape heated metal into desired forms under extreme pressure.

Expert Craftsmanship

Our skilled craftsmen and engineers leverage advanced technologies and traditional techniques to design and manufacture forging moulds that meet stringent industry standards. Each mould is meticulously crafted to withstand the intense pressures and temperatures involved in forging, ensuring reliable performance and longevity.

Materials & Techniques

Material Selection

We carefully select materials for forging moulds based on factors such as heat resistance, wear resistance, and dimensional stability, ensuring optimal performance in demanding forging environments.

Technological Precision

Utilizing CNC machining and precision engineering, we achieve intricate designs and precise geometries in our forging moulds, enhancing the efficiency and quality of the forging process.

Custom Mould Solutions

At Minerva Machinery, we understand the diverse needs of forging applications. Our expert team collaborates closely with clients to design and manufacture custom forging moulds that meet specific requirements, from small-scale components to large industrial parts.

Quality Assurance

Our commitment to quality is embedded in every stage of our mould manufacturing process. Each forging mould undergoes rigorous testing and inspection to ensure it meets exacting standards for dimensional accuracy, surface finish, and performance durability.

Partner With Us

Experience the Minerva Machinery advantage – where craftsmanship meets innovation to deliver forging moulds of unparalleled quality and reliability. Contact us today to discuss your forging mould requirements and discover how we can support your forging operations effectively.

Advanced Forming Solutions for Diverse Applications

At Minerva Machinery, our forming capabilities are designed to meet the complex demands of various industries. Utilizing state-of-the-art technologies, we deliver high-quality components through a range of forming processes, ensuring precision, durability, and optimal performance.

Extrusion

- Process Overview: Extrusion involves forcing material through a die to create long objects with a fixed cross-sectional profile.

- Applications: Pipes, tubes, rails, and complex profiles for the automotive, aerospace, and construction industries.

- Materials: Aluminum, copper, steel, and various alloys.

Forging

- Process Overview: Forging involves shaping material through compressive forces, producing parts with superior strength and structural integrity.

- Applications: Automotive components, aerospace parts, heavy machinery, and industrial equipment.

- Materials: Steel, aluminum, titanium, super alloys, and heat-resistant alloys.

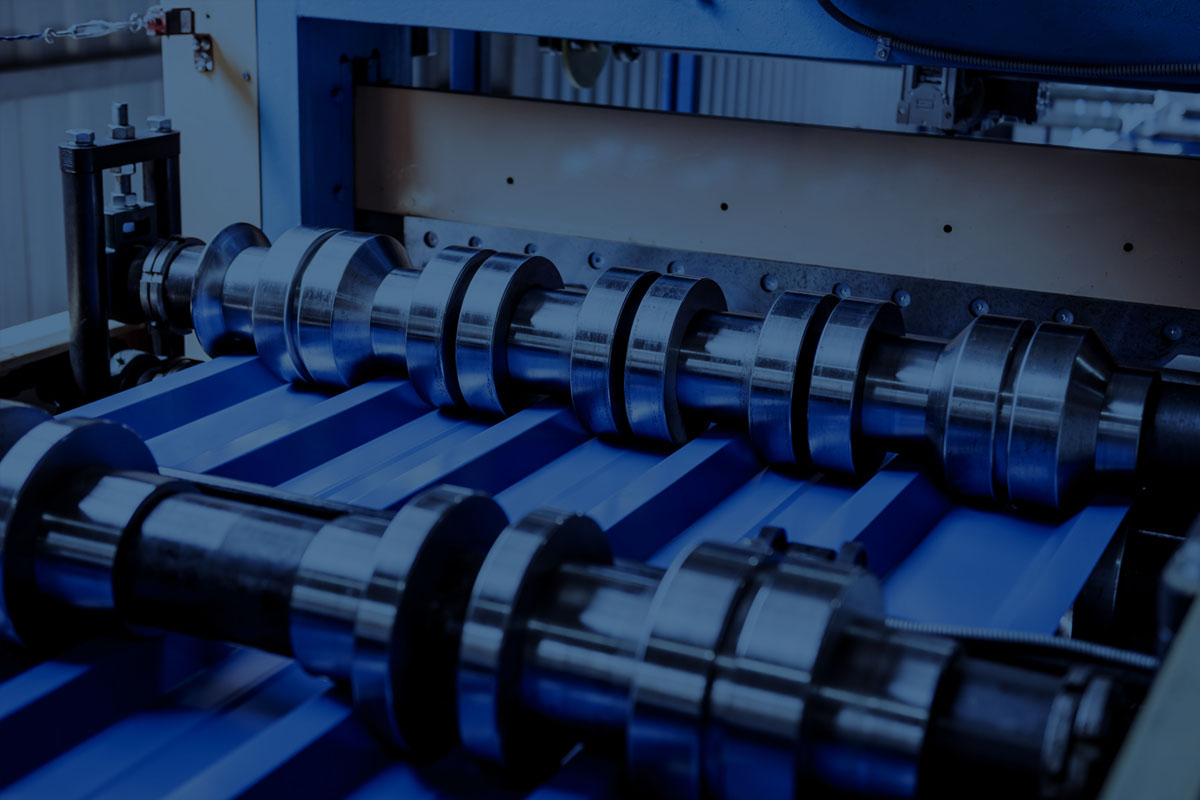

Rollforming

- Process Overview: Rollforming is a continuous bending operation in which a long strip of sheet metal is passed through sets of rolls to form desired shapes.

- Applications: Structural components, automotive parts, and construction materials.

- Materials: Steel, aluminum, and stainless steel.

Similar Processes

- Bending: Precision bending for creating complex shapes and angles in sheet metal and tubular components.

- Stamping: High-speed stamping for producing intricate parts with consistent quality and accuracy.

- Drawing: Deep drawing for manufacturing deep, hollow shapes from sheet metal.

- Spinning: Metal spinning for forming symmetrical, round parts with high precision.

Custom Forming Solutions

At Minerva Machinery, we understand that every project is unique. That’s why we offer customized forming solutions tailored to your specific requirements. Whether you need standard components or complex, high-precision parts, our team of experts is dedicated to delivering innovative solutions that exceed your expectations.

Our forming processes are supported by advanced technologies and rigorous quality control measures, ensuring that each component meets the highest standards of performance and reliability. From initial design to final production, we work closely with our clients to ensure their exact specifications are met.

Experience the Minerva Machinery advantage – where cutting-edge forming technologies and a commitment to excellence come together to create superior components for your business. Contact us today to learn more about our forming capabilities and how we can support your manufacturing needs.